Outdoor Fiber Cable Overview

Overview

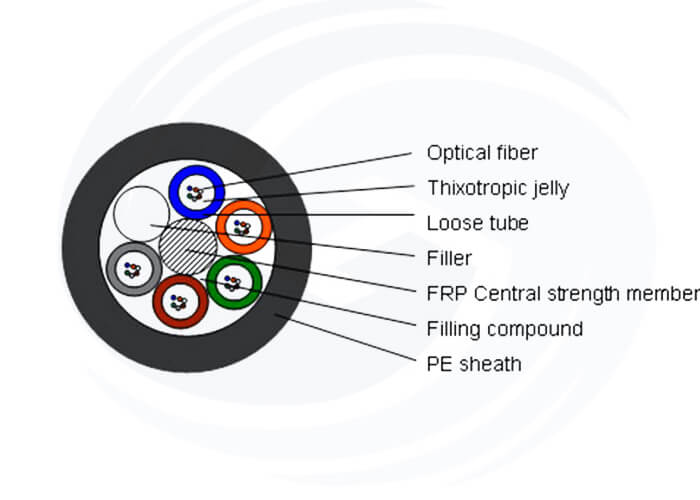

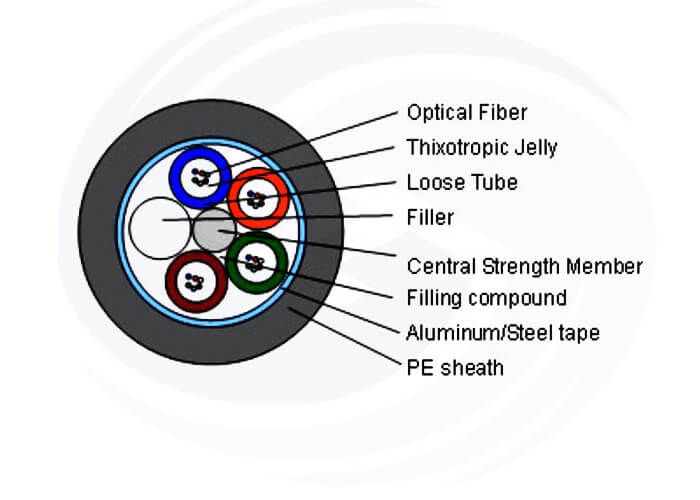

A fiber-optic cable, also known as an optical-fiber cable, is an assembly similar to an electrical cable but containing one or more optical fibers that are used to carry light. The optical fiber elements are typically individually coated with plastic layers and contained in a protective tube suitable for the environment where the cable is used. Different types of cable are used for fiber-optic communication in different applications, for example long-distance telecommunication or providing a high-speed data connection between different parts of a building. Hondao offer various of fiber optical cable .

PACKING AND DRUM

1. The cable is wound on a non-returnable wooden drum. Both ends of cable are securely fastened to drum and sealed with a shrinkable cap to prevent ingress of moisture. The following information shall be marked on the outer sheath of the cable at an interval of about 1 meter.

- Cabletype and number of optical fiber

- Manufacturername

- Month and Year of Manufacture

- Cable length

The sequential number of the cable length shall be marked on the outer sheath of the cable at an interval of 1meter ± 1%.

2. Drum marking, Each side of every wooden drum shall be permanently marked in a minimum of 2.5~3 cm high lettering with following:

- Manufacture name and logo

- Cable length

- Cable type and number of fibers

- Roll way

- Gross and net weigh

PRODUCT PHOTOS

PRODUCT PARAMETERS

Optical fiber characteristics (G.652D FIBER)

Category |

Description |

Specifications | |||

Before cabling |

After cabling | ||||

| Optical Specifications |

Attenuation @1550 nm | ≤0.15 dB/km (max.) | ≤0.18 dB/km (max.) | ||

Attenuation @1625 nm | ≤0.2dB/km | ≤ 0.22 dB/km | |||

Zero Dispersion Wavelength |

≤1520 nm | ||||

Zero Dispersion Slope | ≤ 0.084 ps/nm2·km | ||||

| Polarization Mode Dispersion(PMD) |

≤0.08 ps/km | ||||

Cable Cutoff Wavelength (λcc) | ≤1450 nm | ||||

Macro bending Loss (1 turn; Ф32 mm) @1550 nm (100 turns; Ф60 mm) @1625 nm (100 turns; Ф50 mm) @1310 &@1625 nm |

≤ 0.05 dB ≤ 0.05 dB ≤0.05 dB | ||||

Mode Field Diameter

| @1550 nm | 9.6±0.5μm | |||

Dimensional Specifications |

Cladding Diameter |

124.8 ±0.7μm | |||

Core/clad concentricity error | ≤0.6μm | ||||

Cladding Non-Circularity | ≤1.0% | ||||

Mechanical Specifications | Min bending radius | 12.5D (static) | 25D (dynamic) | ||

| Proof Test level | ≥1.2% | ||||

| Fiber Curl Radius | ≥4.0m | ||||

| Peak Coating Strip Force | 0.9~6.8N | ||||

Fiber coding,The color coding of the optical fiber shall be in accordance with the table

| No. of fiber | 1 | 2 | 3 | 4 | 5 | 6 |

| Color of fiber | Blue | Orange | Green | Brown | Grey | White |

| No. of fiber | 7 | 8 | 9 | 10 | 11 | 12 |

| Color of fiber | Red | Black | Yellow | Violet | Pink | Turquoise |

TEST REQUIREMENTS

| No | Item | Test standard | Method | Acceptance criteria |

| 1 | Tensile test | IEC-60794-1-E1 | -Max. Tensile strength:1500N -Sample length:50 meters -Time: 1minutes; | -Fiber strain at maximum Load: max. 0.10% -Attenuation increase≤0.10dB |

| 2 | Crush test | IEC-60794-1-E3 | -Load: Max. Crush Resistance: 1000N -Time: 1 minutes -Length: 100mm | -No splits or cracks in the outer jacket; -Attenuation increase<0.10dB, |

| 3 | Impact test | IEC-60794-1-E4 | -Impact energy: 450g – Height:1 meter -Number of impacts: 5 | -No splits or cracks in the outer jacket -Attenuation increase≤0.03dB |

| 4 | Repeated bending | IEC-60794-1-E6 | -R=20×cable outer diameter -1m cable length with 150N weight, 30 cycles | – No splits or cracks in the outer jacket -Attenuation increase ≤0.03dB |

| 5 | Torsion test | IEC-60794-1-E7 | -1m cable length with 150N weight -±90 degrees, 10 cycles | – No splits or cracks in the outer jacket -Attenuation increase ≤0.03B |

| 6 | Bending test | IEC-60794-1-E11 | -Diameter of mandrel: 20×D -Number of turns/helix:10 -Number of cycles: 5 | -No damage to the outer jacket – No fiber break -Reversible |

| 7 | Temperature cycling test | IEC-60794-1-F1 | -Temperature step: +20℃→-40℃→+60℃→-40℃→ +60℃ →+20℃ -Time per each step: 12 hrs -Number of cycles: 2 cycles | -Attenuation variation for reference value(the attenuation to be measured before test at +20±3℃) ≤0.05dB, |

| 8 | Water penetration test | IEC-60794-1-F5 | -Water height: 1m -Sample length:3m -Duration of test: 24hrs | -No water leakage at the end of the sample |

| 9 | Drip test | IEC-60794-1-E14 | -Five 0.3m samples suspended vertically in a climate chamber, raised temperature to +70℃ | -No filling compound shall drip from tubes after 24 hr |